Skip to navigation

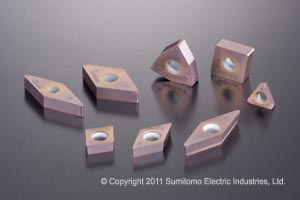

Skip to contentGeneral Features

-

Improved hardness and heat resistance with high purity ceramic binder.

-

Highest wear resistance among the Uncoated SUMIBORON series.

-

For high speed, continuous to light interrupted turning of Hardened Steel.

General Features

-

Significant improvements in wear and fracture resistance by using high purity ceramic binder.

-

General purpose grade for typical Hardened Steel turning.

-

For continuous to medium interrupted turning of Hardened Steel.

General Features

-

High density medium-grained CBN content grade with superior sharpness and wear resistance.

-

For high speed finishing of Grey Cast Iron.

-

For high efficiency machining of Powdered Metal components.

-

For machining of Exotic Alloys.

General Features

-

High density micro-grained CBN content grade with superior fracture resistance.

-

For finishing of Powdered Metal components with high quality surface.

General Features

-

Superior wear resistant substrate coupled with a special Ceramic coat for excellent wear resistance.

-

Optimized balance of wear and chipping resistance for high speed applications.

-

High speed machining of Hardened Steel of more than Vc=200m/min.

General Features

-

Optimized fracture and wear resistance substrate coupled with a smooth Ceramic coat.

-

Achieving high dimensional accuracy and excellent 1.6S surface finish.

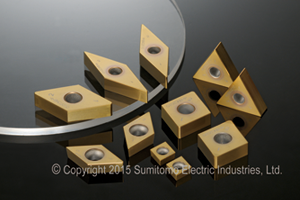

General Features

-

1st Choice grade for Hardened Steel machining.

-

For high efficiency continuous to interrupted turning applications.

-

Suitable for applications with heavy cutting loads from large depths of cut.

-

Utilized with SV-type chipbreaker for removal of carburized layer.

General Features

-

Extra-tough CBN substrate coupled with a highly wear resistant Ceramic coat.

-

Stable dimensional accuracy and surface finish even in interrupted turning applications.

-

Good tool life even in applications with a mixture of continuous and interrupted machining.

General Features

-

Significant improvements in wear and fracture resistance by using high purity ceramic binder.

-

World’s first coated CBN grade for turning of Ductile Cast Iron.

-

Achieves stability under high speed conditions (Vc=400m/min and above).

-

Supports high precision machining with stable surface finish.

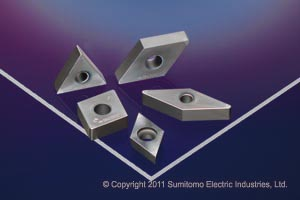

General Features

-

Newly developed CBN substrates and ceramic coating improve machining accuracy and tool life.

-

BNC2010 for high precision finish with good dimensional accuracy and surface finish.

-

BNC2020 for general purpose Hardened Steel machining with better stability.

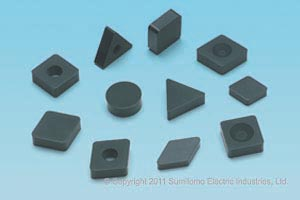

General Features

-

100% Solid CBN structure for high speed finishing to roughing of Grey Cast Iron.

-

Excellent balance of wear resistance and toughness to achieve high precision machining.

-

All corners of the insert, along with the whole cutting edge length, can be utilized.

-

Used with specially designed RM type milling cutter for high speed roughing of Grey Cast Iron.

General Features

-

High density ultra-fine grained polycrystalline diamond.

-

World’s best wear resistance and strength among all PCD grades.

-

High efficiency and high precision machining of all Aluminum and non-ferrous alloys.

-

Suitable for both roughing and finishing applications.