recycling

Let’s recycle!

- CSR

- Recycling of carbide tools

- Let’s recycle!

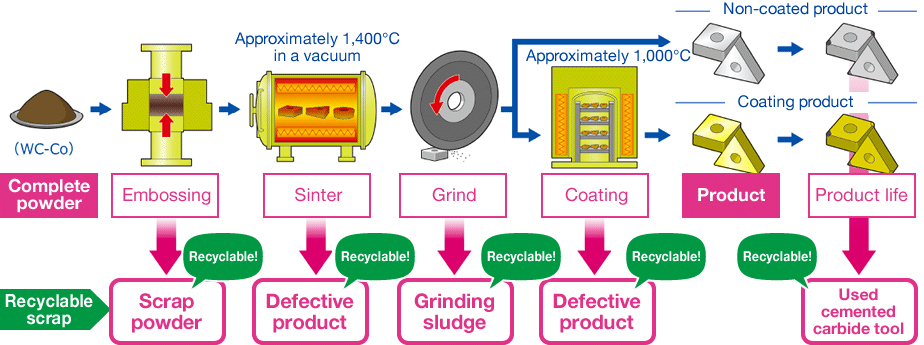

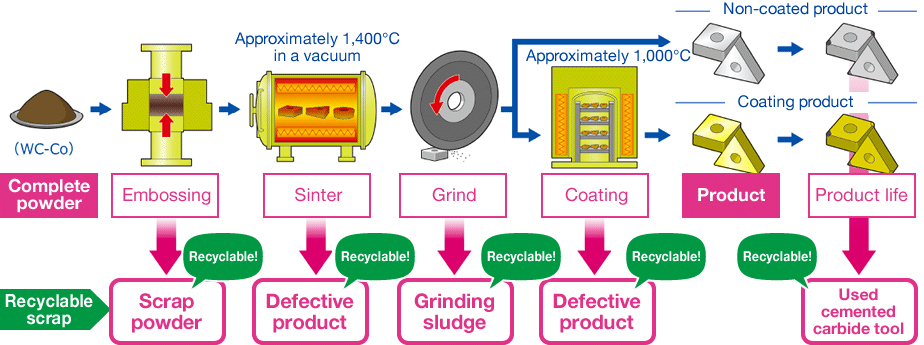

Retains constituents and recycles them into powder.

It has advantages such as “its minimized energy consumption", “its reduced CO2“, “its eliminated use of chemicals", and “its potential processing at small-sized facilities", etc.

[Zn: Zinc Co: Cobalt WC: Tungsten carbide]

![Image:[Zn: Zinc Co: Cobalt WC: Tungsten carbide]](https://www.sumitool.com.au/wp-content/uploads/2022/09/img-recycling1.png)

![Image:[Zn: Zinc Co: Cobalt WC: Tungsten carbide]](https://www.sumitool.com.au/wp-content/uploads/2022/09/img-recycling2.jpg)

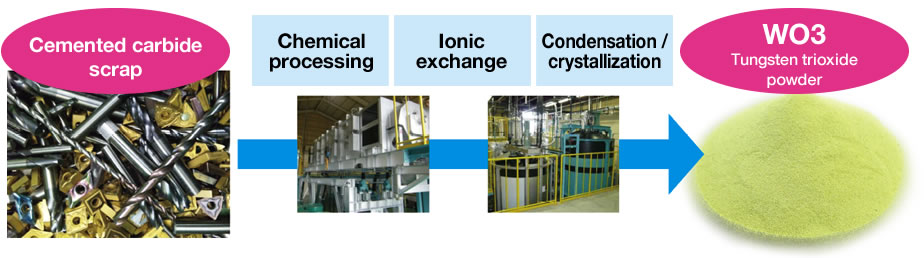

Recycles scrap to an intermediate tungsten material, tungsten trioxide (WO3).It has advantages such as “its quality equivalent to ore refining" and “its wider availability (granularity)".

It also includes scrap from a production phase of anything other than the cemented carbide tools.

(For further information on recyclable items, contact our representatives as shown below.)

Sumitomo Group provides dedicated representatives in three areas; Tokyo, Nagoya, and Osaka to support the recycling of scrap.

Thank you for your cooperation in our recycling efforts as we would like to keep on enhancing this activity.