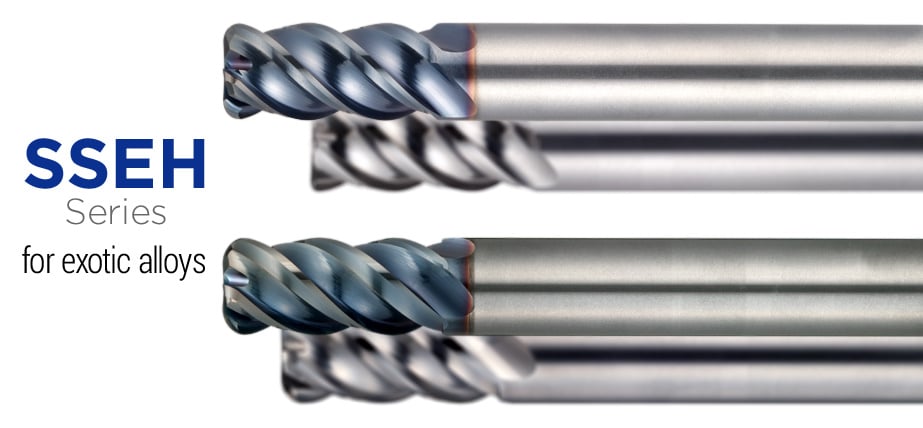

SSEH series – Radius endmill for exotic alloys

SSEH series - Radius endmill for exotic alloys

Adopts a strong helical angle to provide improved edge sharpness with smooth and reliable chip evacuation

Superior edge sharpness and chip evacuation ability

Adopts a strong helical angle (45° helical) to provide improved edge sharpness with smooth and reliable chip evacuation.

High rigidity tool

Optmizing core thickness, flute shape and size to obtain both tool rigidity and chip evacuation ability.

Improved adhesion resistance

Combination of a near mirror-finish flute surface with a specialized coating layer improve adhesion and wear resistance.

Improved fracture resistance

Unique smooth radius profile helps to soften cutting shock and improve fracture resistance.

Specialized coating

A super-smooth coating with significantly improved coating hardness and heat resistance help to improve tool life in cutting heat resistive alloy.

Anti-vibration type added to the SSEH series endmill for exotic alloys