Skip to navigation

Skip to content

General Features

-

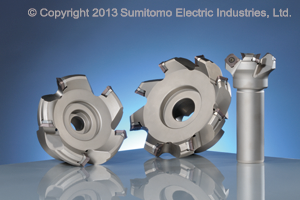

For both shoulder and face milling operations.

-

Double-sided, polygonal inserts with 6-corners for high efficiency milling.

-

Cutter body ranges from Dia25mm to Dia200mm.

-

Available Standard, Fine-pitched, Extra-fine pitched and Shank type configurations.

General Features

-

Indexable face mill that can be use with 2 different insert geometries.

-

Double-sided, square inserts with 8-corners for high cutting performance.

-

Double-sided, octagonal inserts with 16-corners for better economy.

-

Cutter body ranges from Dia40mm to Dia250mm.

-

Available Standard, Fine-pitched, Extra-fine pitched and Shank type configurations.

General Features

-

Strong edged, indexable face mill series with 8 cutting edges.

-

3 cutter body configurations for high feed to large DOC applications.

-

Special chipbreakers available for both Cast Iron and Cast Steel materials.

General Features

-

Strong edged, versatile, super high feed indexable endmill series.

-

Unique insert shape for extra strength and cutting performance with highly durable cutter bodies.

-

4 insert sizes utilized for cutter diameters ranging from Dia16mm to Dia100mm.

General Features

-

Indexable face mill series with tangentially mounted inserts for extra cutting edge strength.

-

For high efficiency, semi shoulder milling with a max. DOC of 15mm.

-

Cutter body ranges from Dia80mm to Dia200mm.

General Features

-

Indexable face mill series with tangentially mounted inserts for extra cutting edge strength.

-

Cutter body with 2-stepped insert configuration for deep shoulder milling.

-

Precision molded inserts with nicked cutting edges for low cutting resistance.

-

Cutter body ranges from Dia80mm to Dia250mm.

General Features

-

Indexable endmill series with round inserts for exotic alloy machining.

-

Ultra-high rake and high rigidity body design promotes low cutting resistance and low vibrations.

-

Proprietary insert positioning mechanism increases tool operability and higher accuracy.

General Features

-

Indexable endmill series for versatile, high efficiency milling of Non-ferrous alloys.

-

High rake insert design coupled with Uncoated H1 or AURORA Coat DL1000 grades.

-

Holders range from Dia20mm to Dia125mm in shank and shell type cutter bodies.

General Features

-

Indexable endmill series with precision construction and strong cutting edge design.

-

Holders range from Dia14mm to Dia125mm in shank and shell type cutter bodies.

-

6 types of chipbreakers including the new E and EH types for Stainless Steel machining.

General Features

-

4 cornered square insert for shoulder milling with excellent squareness.

-

High precision construction with optimized insert design for superior machined finish.

-

Holders range from Dia40mm to Dia250mm in shank and shell type cutter bodies.

General Features

-

Improved run-out precision for better machined surface quality.

-

Extra-high rake with special cutting edge configuration for improved edge sharpness.

-

Special FG-chipbreaker designed to greatly reduce burr.

General Features

-

Multi-teeth indexable endmill for heavy roughing.

-

Lead groove and special pocket design for smooth chip evacuation.

-

Holders range from Dia20mm to Dia100mm in shank and shell type cutter bodies.

General Features

-

Indexable endmill series for a variety of machining applications such as pocketing and ramping.

-

4 insert sizes utilized for cutter diameters ranging from Dia20mm to Dia160mm.

-

Surfing inserts for anti-vibration, rough milling and a special chipbreaker for Aluminum alloys.