Skip to navigation

Skip to content

General Features

- Grooving system that uses triangular inserts with molded chipbreaker.

- Good chip control during groove bottom touch-up with traverse tool movement.

- Grooving widths range available from 1.4mm to 4.5mm.

General Features

- Doubled ended boring bars with overhang capabilities of up to 5D.

- Boring diameter ranges from Dia2.0mm to Dia5.0mm in 0.5mm diameter increments.

General Features

-

For small diameter boring from Dia1.0mm to Dia5.0mm.

-

Simple and strong insert clamping with high indexing accuracy and repeatability.

-

Available in various holder types such as square, round and L-styled.

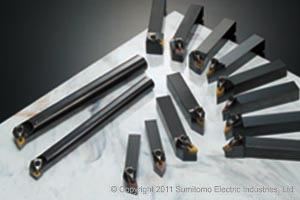

General Features

-

High rigidity double clamp system with high indexing precision.

-

Excellent for high efficiency machining, interrupted machining and Hardened Steel machining.

-

Available in external holders and internal boring bars for different ISO insert shapes.

General Features

-

One-piece tool holder construction for improved rigidity and lower vibration.

-

Wide selection of holder configuration for external, internal and face grooving.

-

Wide selection of chipbreakers that caters to a variety of machining processes such as grooving,

traverse feed, profile turning and cut-off.

General Features

-

Wide chipbreaker design with sharp cutting edge produces excellent surface finish.

-

Available in 3 types of cutting edge lengths.

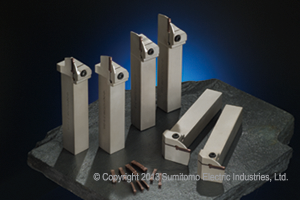

General Features

-

High rigidity double clamp system with high indexing precision.

-

Excellent for high efficiency machining, interrupted machining and Hardened Steel machining.

-

Available in external holders and internal boring bars for different ISO insert shapes.

General Features

-

High efficiency diameter reduction for long shanks with plunging actions.

-

Coin-shaped chip produced does not entangle the holder.

-

Zero off-set cutting edge design with 4mm, 5mm and 6mm insert widths.

General Features

-

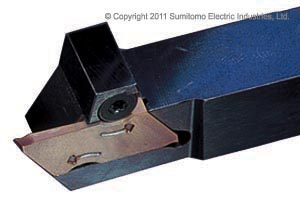

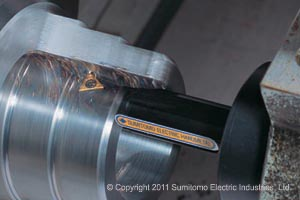

External tool holder series for gang-type autolathes.

-

Different types of special purpose inserts can be use on a single common holder.

-

Special carbide insert grades for high precision machining of very small components.

General Features

-

3-cornered inserts with 3-D molded chipbreaker for stable chip control.

-

Polished cutting edge flank faces to achieve high quality threads.

-

A wide selection of thread types for general, Oil & Gas and Aerospace industries.

General Features

-

Affordable anti-vibration boring bar series with a tool overhang of up to 5D.

-

Featuring a simple but Effective Chattering Killer System (ECKS).

-

New boring head design for improved rigidity and excellent chip evacuation.

General Features

-

External turning holder series for gang-type autolathes.

-

Tool point compensation not required.

-

Available in a wide variety of holder styles for different ISO insert shapes.